After Advanced Nutrition's advice and using DC X-Zel for our transition cows we have found they are fitter and healthier. They don’t lose much condition after they calve, right through to lactation. They just calve down better.

Winner maximises feed efficiency within a robotic milking system

Cream Award Winner Tom Nicholls is constantly striving to push efficiencies on his dairy farm. How is he maximising forage use in a robotic milking system? British Dairying finds out.

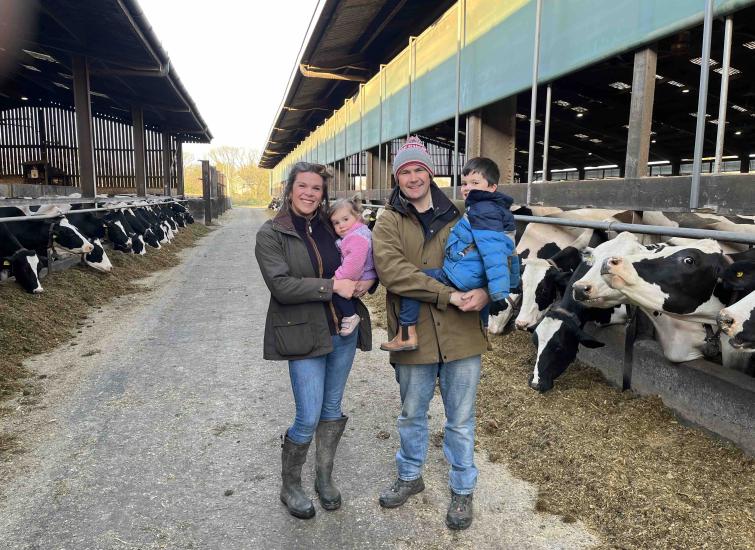

Tom and Kate Nicholls run a highly efficient dairy enterprise in Cornwall, working alongside their dedicated farm team. The dairy operation comprises 450 Holstein cows with approximately 375 milked through seven Lely robots. The milk is supplied to Rodda’s Creamery, with a focus on butterfat. Homegrown multi-cut silage, maize, and cereals are utilised as feed for the dairy herd, maximising efficiency.

The team are always striving for the best, both for their cows and the business. Part of the reason for installing the robots 14 years ago was to help enhance farm performance. The family had a clear goal in mind: to create the most comfortable and productive environment for their cows. While installing the robots brought immediate gains, this was just part of their journey towards continuous improvement.

The wider farm team, including consultant vet Phil Elkins, nutritionist and Technical Manager, Scott Carter from Advanced Ruminant Nutrition and the team at Genus are together focusing on several key areas to drive improvement and efficiency.

Improving herd health, fertility and cow longevity is at the core of their approach. The farm has a target to increase lifetime milk by 15%. From a health perspective they focus on prevention rather than treatment - reducing disease and the need for intervention as much as possible.

The team continually review breeding strategies to progress the genetic potential of the herd. They have a clear vision for breeding the ideal animals to maximise their investment, with a particular focus on milk quality, compatibility with robotic milking, and longevity, all without sacrificing production potential.

Following changes to cubicles, upgrading of mattresses and a regular mobility scoring with actionable outcomes, the team maintain a low stress environment for their cows and keep lameness levels low too.

Each year, the Acland Farm team identify new opportunities to enhance efficiency. In 2024, Tom began looking at amino acid balancing to help drive improvements.

“Amino acid balancing has the potential to offer rewards both in performance and in reducing environmental impact,” says Scott Carter.

However, producers need to work closely with their nutritionists to accurately balance, which can be a complex process.

“There isn’t a blanket feed rate for amino acids (AA’s). To determine what is best for the herd, the current diet being fed needs to be analysed. Consideration needs to be given to specific farm targets, such as the milk contract - is it yield, or constituent based, target milk yield or fertility concerns. Additional factors, such as restrictions on certain feed ingredients like soya, must be taken into account. Working alongside the latest nutrition rationing programmes we ensure the correct level of supplementation in grams. These provide a predicted response, allowing us to make an informed decision on whether to proceed,” explains Scott.

“I brought Scott on board as I value his company’s scientific approach to nutrition. They understand how it integrates with the rest of the work we do on the farm, ensuring we maximise the potential of our robotic system,” notes Tom.

The team realised that the benefits to such an approach would allow for more extensive use of alternative protein sources in diets – helping to reduce the feed costs whilst maintaining productivity. It would also reduce the amount of excess dietary protein, therefore reducing nitrogen excretion in the urine and faeces, to have a positive environmental impact.

“The team has been selectively breeding the Holstein cows for high milk fat content for several years. However, nutrition plays a critical role in unlocking this genetic potential. Achieving optimal fat manipulation requires a multifaceted approach. Key factors of consideration include fibre levels in the diet to maintain optimal rumen function and cow health; source and quantity of sugar and starch; as well as tapping into the latest research on dietary fat to enhance milk price and therefore margin per cow,” explains Scott.

‘It’s great to get to work with Tom and his team – they are constantly challenging for the next innovation in dairy nutrition to ensure we are maximising cow health and comfort.”

〈 BACK